Driving towards a Greener Future with

Refractory, Insulation, and Corrosion

Protection

Specialized Solutions for Industries Operating in High Temperature Conditions

REFRACTORY & ACID PROTECTION- THINK LANEXIS!

- Upto 15% Fuel Reduction in Reheat Furnaces

- Energy Saving & Coke Reduction through Blast Furnace Tuyere Insulation

- Upto 20% Increase in EAF Campaign Life

- Extend existing refractory life upto 2X without replacements.

- Upto 20% CO2 reduction for a faster ESG Impact.

- Upto 15% energy saving in Melting Holding Furnaces.

- Increase Ladle Hot Metal Capacity upto 20%

- High Performance Non-Wetting Fused Silica Launders & Filter Bowls for Casthouse

- High Efficiency Green Fluxes for Alkali removal in Furnaces

- Electrolysis Pot insulation & Anode Coatings

- Upto 7% Fuel & CO2 reduction of Fired Heaters & Crackers

- Increase in throughput by 10%, thus increase in performance efficiency

- 'Eliminate' oxidation on fired heater & cracker tubes.

- Reduce Decoking by 50% and increase run length in DCU's.

- Upto 2x Increase of Flare Service Life

- Complete Acid Resistant Linings Systems for Sulphuric Acid Towers & Tanks

- Carbon Brick Lining for Phospohoric Acid Plants

- Protective Coatings for Chemical Attack Zones

- High Service Life Acid Brick Lining Systems for Tanks, Digestors & Floors

- "Corrosion Audits" for existing linings & custom revamps

Lanexis is Trusted By

Get In Touch To Improve your Production Efficiency

Product Range

Mullite Bricks, 99% Alumina Shapes, Alumina Chrome, High Alumina Fireclay Bricks, Fused Silica Shapes, Insulation Bricks, Andalusite Bricks, Super Duty Bricks, Refractory Monolithics.

Microporous Insulation, High Emissivity Coatings, Ceramic Fiber, Advanced Refractory Coatings, LIQUID Insulation, Calcium Silicate, Ultra Low Thermal conductivity backup insulation.

Acid Proof Bricks & Tiles, Carbon Bricks, Furane Mortar, Specialized Membranes- Carbon Filled, Rubber Lining, PTFE, Domes, Grid Bars, Anti Acid Coatings, Novolac Screeds, Metal Coatings.

Certifications and Associations

Meet your ESG Goals with Lanexis

- Reducing CO2 Emissions from Furnaces

- Reducing Hazardous refractory & Insulation waste generated from furnaces.

- "0 Penetration" acid resistant lining systems for protecting the soil & groundwater from harmful acids & chemicals contamination.

- Increasing worker safety by protection from high heat, chemicals, and high dust environments.

Tons of CO2

Total CO2 Emissions Reduced

Innovations

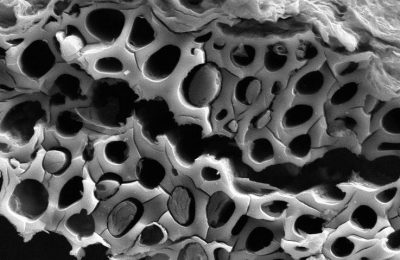

- Next Gen Insulation

Lanexis has partnered with ISRO’s Vikram Sarabhai Space Center to develop the next generation of Silica Insulation inspired from Space Technology.

- Liquid Insulation

World’s first reliable liquid insulation to reduce heat losses, hot spots & corrosion of the Steel shells of Furnaces & Rotary Kilns.

- Activated Carbon Coatings

Development of monolithic activated carbon-based coatings & screeds to protect from acids/alkalis to replace traditional lining systems in Chemical & Fertilizer Industries.