Lanexis mullite refractories are high purity, offer exceptional stability and durability, tailored for applications requiring strong chemical and mechanical stability, high temperature strength, and resistance to spalling, corrosion, and flame impingement. These refractories predominantly contains the mineral phase mullite (3Al2O3 • 2SiO2).

Request a free sample

Key Features

- Low creep

- High thermal spalling resistance

- Excellent thermal shock resistance

- Withstands oxidizing & reducing atmospheres

- Custom Shapes with Low Lead Times

Applications

- Petrochemical Processing

- Carbon Black

- Glass Melting Tanks

- High Temperature Furnaces

- Ceramics Production

Mullite Refractory Range

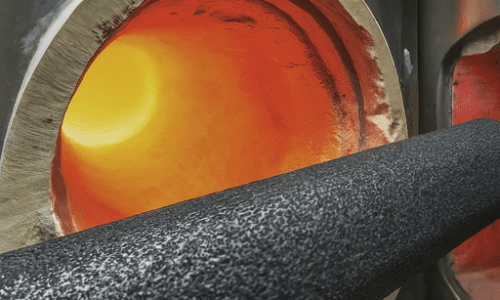

Lanexis Mullite refractories have low creep, high stability & spall resistance at high temperatures. They excel in high-intensity burners, carbon black reactors, glass melting and other extreme temperature and corrosive environments, outperforming conventional refractories.

Technical Specifications

- Chemical Composition: High purity mullite

- Maximum Service Temperature: Up to 1800°C (varies by product)

- Bulk Density: 2.5 – 2.8 g/cm³

- Cold Crushing Strength: 60 – 100 MPa

- Apparent Porosity: 18 – 23%

Sustainable, & reliable energy systems, Find Your Solution Now!

Features

Know More About

The Product

High refractoriness, creep resistance, and volume stability

High erosion resistance and thermal spalling resistance

Excellent thermal shock resistance

Withstands oxidizing and reducing atmospheres effectively

Applications

Pioneering Solutions for Tomorrow's Challenges

Petrochemical Processing Equipment

Carbon Black

High Intensity Burners

Glass Melting Tanks

High Temperature Furnaces

Ceramic Production

0

+

Years of Experience

0

+

Numbers of Customers Worldwide

0

+

Number of Projects Covered

0

Metric Tons of Carbon Emissions Reduction

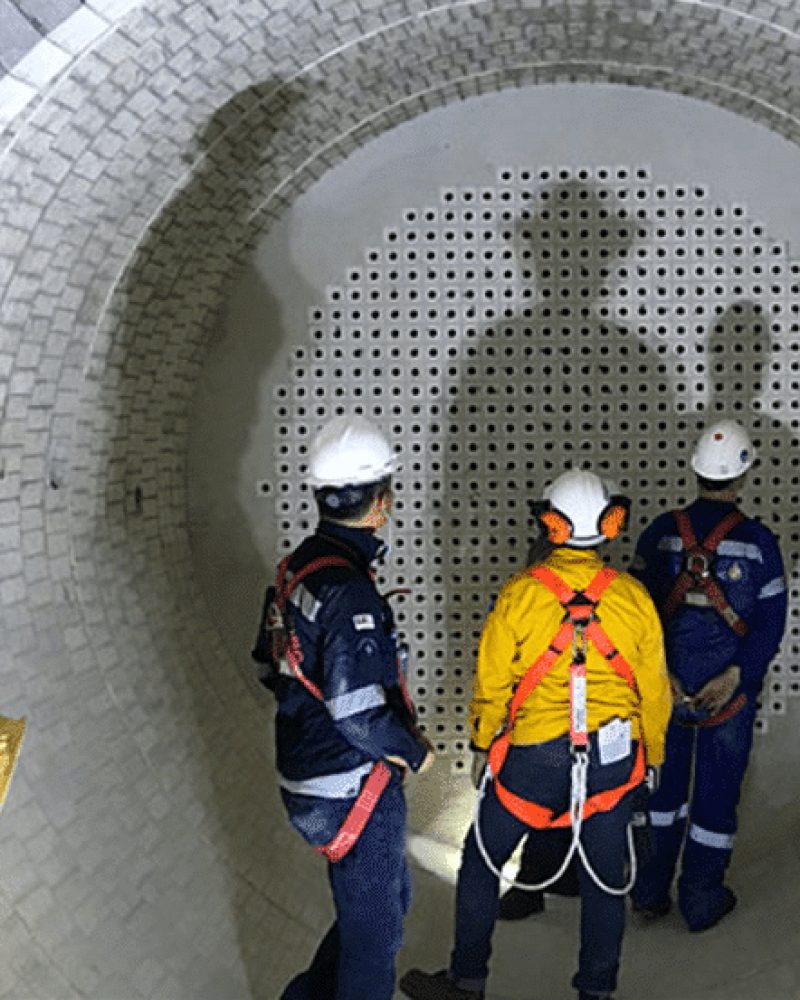

What are Durabricks®?

Durabricks® are premium refractory bricks offered by Lanexis, designed for superior performance and extended service life. These high-quality bricks are engineered for a range of applications providing exceptional durability and high thermal stability. The Durabrick® range includes mullite, andalusite, corundum, insulation & alumina-chrome grades

Active Customers

0

+

Technical Support?

Lanexis also provides design, engineering, and installation support worldwide.

Lanexis is Trusted By

Innovation and Excellence

Advantages at Lanexis

Energy Saving Refractories:

We can reduce energy consumption upto 20%. Lanexis is a leader in reducing fuel consumption of your furnaces through innovative lining matrix, advanced products like High Emissivity coatings & Microporous Insulation.

Customization:

Need specific shapes, sizes, grades or change in refractory properties? Our in-house R&D team allows Lanexis to continuously innovate and customize refractories to meet specific customer needs.

Technical Support:

We provide design, engineering, failure analysis- rectifications and thermal audits for furnaces. Whether you require updated refractory drawings or thermal calculations for a higher energy efficient refractory lining design- we provide complete technical support.

Contact Lanexis today for tailored Mullite Refractory solutions!

Reach out to Lanexis today for customized solutions designed to meet your unique requirements with top-notch quality and performance!

For further inquiries

Have Questions? We’re Here to Help! If you have any questions or need further information, Our team is ready to assist you with any inquiries you may have.