Request a free sample

Key Features

-

High Mechanical Strength: Robust structure suited for high-stress environments.

-

Excellent Thermal Conductivity: Ensures efficient heat transfer.

-

Thermal Shock Resistance: Withstands rapid temperature changes.

-

Chemical Corrosion Resistance: Resistant to slag, alkalis, and acids.

Our Range

-

Nbsic

-

SiC HS Grade

Silicon Carbide Refractory Range

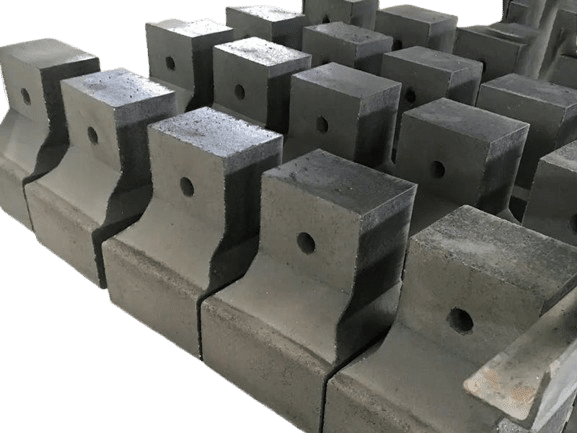

Nitride Bonded Silicon Carbide Refractories

Nitride Bonded Silicon Carbide (NBSiC) Bricks are high-performance refractory materials, combining silicon carbide (SiC) with silicon nitride (Si3N4) for exceptional strength and durability. Catering to applications like:

-

Ceramic Kilns: Lining kiln cars and saggars.

-

Non-Ferrous Metal Furnaces: Ideal for aluminum and copper smelting.

-

Incinerators: Reliable linings for high temperatures and corrosive conditions.

-

Blast Furnaces

Technical Specifications

-

Si₃N₄ (Silicon Nitride) Content: ≥ 20%

-

SiC (Silicon Carbide) Content: ≥ 72%

-

Fe₂O₃ (Iron Oxide) Content: ≤ 1.0%

-

Bulk Density: ≥ 2.65 g/cm³

-

Apparent Porosity: ≤ 17%

-

Cold Crushing Strength: ≥ 150 MPa

-

Cold Modulus of Rupture: ≥ 45 MPa

-

Thermal Conductivity: ≥ 15 W/m.K

Sustainable, & reliable energy systems, Find Your Solution Now!

Features

Know More About

The Product

High Mechanical Strength:

Suitable for high-stress environments.

Excellent Thermal Conductivity:

Efficient heat transfer.

Thermal Shock Resistance:

Withstands rapid temperature changes.

Chemical Corrosion Resistance:

Resistant to slags, alkalis, and acids.

Applications

Pioneering Solutions for Tomorrow's Challenges

0

+

Years of Experience

0

+

Numbers of Customers Worldwide

0

+

Number of Projects Covered

0

Metric Tons of Carbon Emissions Reduction

What are Durabricks®?

Durabricks ® are premium refractory bricks offered by Lanexis, designed for superior performance and extended service life. These high-quality bricks are engineered for a range of applications providing exceptional durability and high thermal stability. The Durabrick® range includes mullite, andalusite, corundum, insulation & alumina-chrome grades.

Active Customers

0

+

Technical Support?

Lanexis also provides design, engineering, and installation support worldwide.

Lanexis is Trusted By

Innovation and Excellence

Advantages at Lanexis

Energy Saving Refractories:

We can reduce energy consumption upto 20%. Lanexis is a leader in reducing fuel consumption of your furnaces through innovative lining matrix, advanced products like High Emissivity coatings & Microporous Insulation.

Customization:

Need specific shapes, sizes, grades or change in refractory properties? Our in-house R&D team allows Lanexis to continuously innovate and customize refractories to meet specific customer needs.

Technical Support:

We provide design, engineering, failure analysis- rectifications and thermal audits for furnaces. Whether you require updated refractory drawings or thermal calculations for a higher energy efficient refractory lining design- we provide complete technical support.

Contact Lanexis today for tailored Silicon Carbide Refractory solutions!

Reach out to Lanexis today for customized solutions designed to meet your unique requirements with top-notch quality and performance!

For further inquiries

Have Questions? We’re Here to Help! If you have any questions or need further information, Our team is ready to assist you with any inquiries you may have.