Request a free sample

Key Features

-

Superior thermal insulation for high-temperature applications.

-

Reduces fuel consumption by 10% to 25%, cutting operational costs.

-

Prevents oxidation and corrosion of metals, increasing durability.

-

Extends equipment lifespan, minimizing downtime and repairs.

-

Environmentally friendly with no VOCs, reducing harmful emissions.

Applications

-

Reheat & Forge Furnaces

-

Ladle & Tundish Preheater

-

Fired Heaters & Crackers

-

Melting Furnaces

-

Tunnel & Shuttle Kilns

-

Hot gas ducts

Ceramic Fibre Veenering System Range

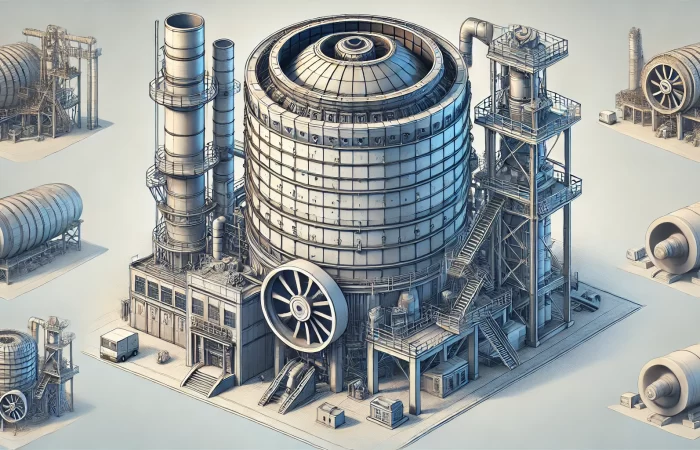

Ceramic Veneering Technology

Lanexis offers a revolutionary veneering technology for high energy saving in Furnaces. Our veneering technology comprises of a thin layer of ceramic fiber blanket soaked in a proprietary ceramic coating which is applied on top of existing Refractory surfaces without anchoring!

“No need to replace existing refractories”- add a tough, high service life veneer on top.

The proprietary coating has extremely high adhesion and does not require any additional anchoring.

Designed to protect refractory and metal surfaces, these coatings reflect radiant heat back into furnaces, forges, and equipment, improving efficiency, energy savings, and production quality.

With no volatile organic compounds (VOCs), these environmentally-friendly coatings help reduce emissions and protect both equipment and the planet. Their superior bonding strength and re-radiative properties make them ideal for preventing oxidation, corrosion, and thermal fatigue, while also ensuring durability and longevity in industrial use

Technical Specifications

-

Rated temperature: Upto 1700c (3500°F)

-

Material: Electrically non-conductive ceramic coating

-

Adhesion: Superior bonding to all refractory and metal surfaces (ferrous and non-ferrous)

-

Thermal Performance: Reflects radiant heat back to maximize energy efficiency

-

Re-radiative properties: Absorbs and releases energy efficiently

-

Fuel Consumption Reduction: Upto 18% average savings

-

NOx Reduction: 5% to 7% reduction in emissions

Sustainable, & reliable energy systems, Find Your Solution Now!

Features

Know More About

The Product

Energy Savings

Our ceramic veneers reflect radiant heat back into furnaces, improving energy efficiency and lowering fuel consumption by 10% to 25%, which can also lead to potential tax benefits.

Reduce Shutdown Time

No need to replace the existing refractories, put a new layer of high performance, highly insulating veneer on top without any anchoring.

Durability and Longevity

The strong bonding prevents oxidation, corrosion, and fatigue, extending the lifespan of equipment, reducing maintenance costs, and minimizing downtime.

Environmental Benefits

The coating contains no VOCs and reduces harmful emissions like NOx by 5% to 7%, making processes cleaner and more efficient.

Applications

Pioneering Solutions for Tomorrow's Challenges

Reheat Furnaces

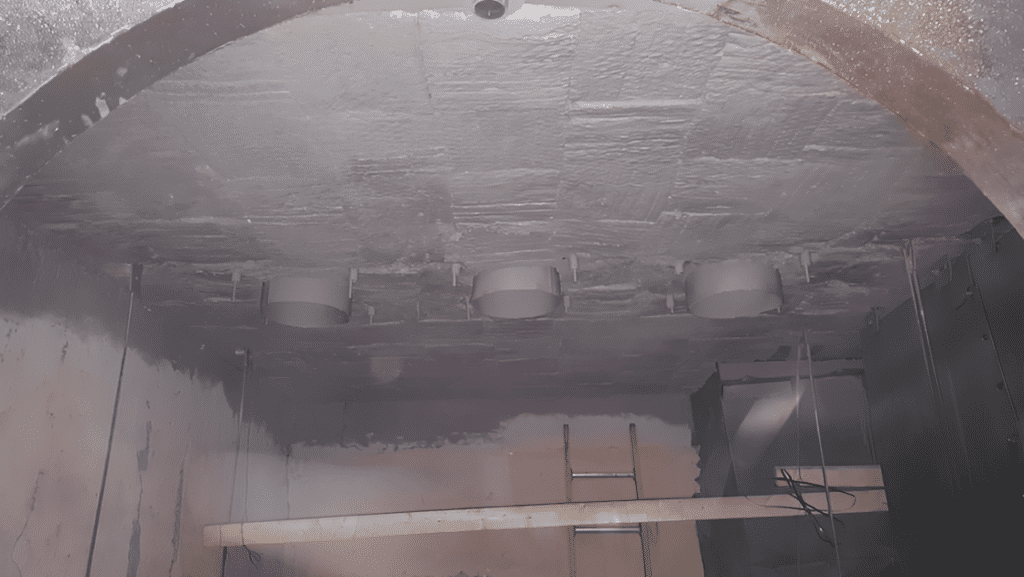

Before

Before

Walking Beam Furnace Skid & Post

After

After

0

+

Years of Experience

0

+

Numbers of Customers Worldwide

0

+

Number of Projects Covered

0

Metric Tons of Carbon Emissions Reduction

Why Buy This Over Competition

Lanexis is an internationally trusted engineering company, offering comprehensive refractory, acidlining, and insulation solutions. Our technical team collaborates closely with customers to customize products for improved efficiency and cost-effectiveness. With professionally managed operations and swift response times, we provide seamless support from offers to after-sales service.

Active Customers

0

+

Technical Support?

Lanexis also provides design, engineering, and installation support worldwide.

Lanexis is Trusted By

Innovation and Excellence

Advantages at Lanexis

Customized Solutions

Lanexis offers customized calcium silicate insulation solutions tailored to your specific requirements, ensuring optimal performance and cost-effectiveness across various industries and applications.

Quality Assurance

We prioritize quality in our products and services, ensuring that our calcium silicate insulation meets the highest standards of performance, reliability, and durability, providing you with confidence and peace of mind in your investment.

Responsive Support

With Lanexis, you can expect responsive and dedicated customer support throughout the entire process, from consultation to installation and beyond. Our team is committed to providing prompt assistance, timely updates, and proactive problem solving to meet your unique needs and challenges.

Contact Lanexis today for tailored Ceramic Fibre Veenering System solutions!

Reach out to Lanexis today for customized solutions designed to meet your unique requirements with top-notch quality and performance!

For further inquiries

Have Questions? We’re Here to Help! If you have any questions or need further information, Our team is ready to assist you with any inquiries you may have.