OUR SOLUTIONS

Optimise Aluminium Production and Lower Energy Consumption with Lanexis

Request a free sample

Energy Saving in Furnaces

- Achieve up to 15% Fuel Reduction

- Reduce Carbon & GHG Emissions

- Minimize Heat Losses Between Charges

- Faster Heatup & Cooldown

- With Our Advanced Refractory Coatings

Dross Reduction

- Reduce Dross by up to 10%

- Technology: Alter Heat Re-Radiation of Furnace Wall & Roof Refractory

- Controlled Furnace Temperatures Result in Dross Reduction

- Reduce Dross without Process Alteration

- Applicable to Existing Furnaces without Refractory Change

- With Emisshield High Emissivity Coatings

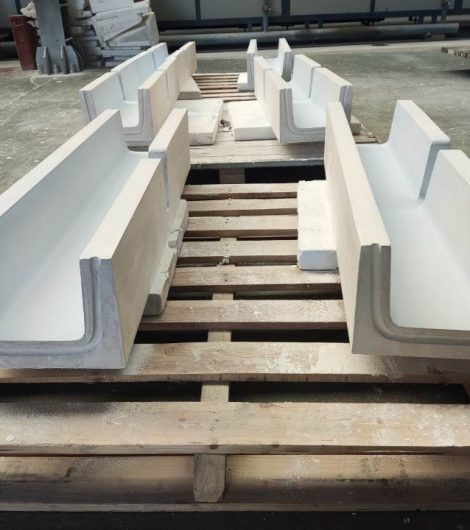

High-Performance Aluminum Transfer Troughs / Launder / Filter Bowls

- Highly Thermal Shock Resistant

- Ensures Better Melt Quality with Zero Contamination

- Low Downtime with High Service Life

- Utilizes Grades up to 99% Fused Silica

- With Lantuff Fused Silica Shapes

Increase Ladle Capacity

- Utilize Specialized Microporous Insulation to Reduce Insulation Thickness

- Microporous Insulation Decreases Metal Temperature Drop

- Ideal for Road Transfer Ladles

- No Refractory Lining Change Required

- Lanexis increased ladle volume by 15%, by changing ceramic fibre

High Efficiency- Green Fluxes for Alkali Removal

- Efficiently Remove Alkalis (Na,Ca,Li) and Non-Metallic Inclusions (Especially Oxides)

- Achieve Sodium Levels Less than 1 ppm even in High Mg-Al Alloys

- Non-Toxic with No Fluorides or Harmful Emissions

- Low Melting Point- Melts below 480°C (900°F)

Lanexis is Trusted By