OUR SOLUTIONS

Increase Steel Production and Lower CO2 Emissions with Lanexis

Request a free sample

Energy Saving & Coke Reduction through Blast Furnace Tuyere Insulation

- Ultra-Low Thermal Conductivity for Thin Insulation in Pen Stocks, Blowpipe

- Reduces Heat Losses & Increases Safety

- Customized System for Tuyere Sizes

- Easy Installation & Water Repellent

Fuel Reduction & Production Increase in Reheating Furnaces

- Reduce Fuel Consumption up to 15%

- Diverts Radiant Energy Losses to Product, Reducing Burners

- Thin Coating on Refractory/Fibre Walls & Roof, Quick Spray Installation

- Keeps Refractories Cooler, Increases Lifespan up to 2x

- With Lanexis Advanced Refractory Coatings and Veneering Systems

Reduce EAF Downtime & Increase Electrode Life Upto 25%

- Proven Electrode Life Increase, ROI less than 30 Days

- Decrease Arcing Time per Melt

- Reduce Cooling Tube Damage from Thermal Degradation

- Increase Heat Transfer of Cooling Tubes

- Reduce Heat Losses and Carbon Footprint

- With Lanexis Advance Coatings Systems

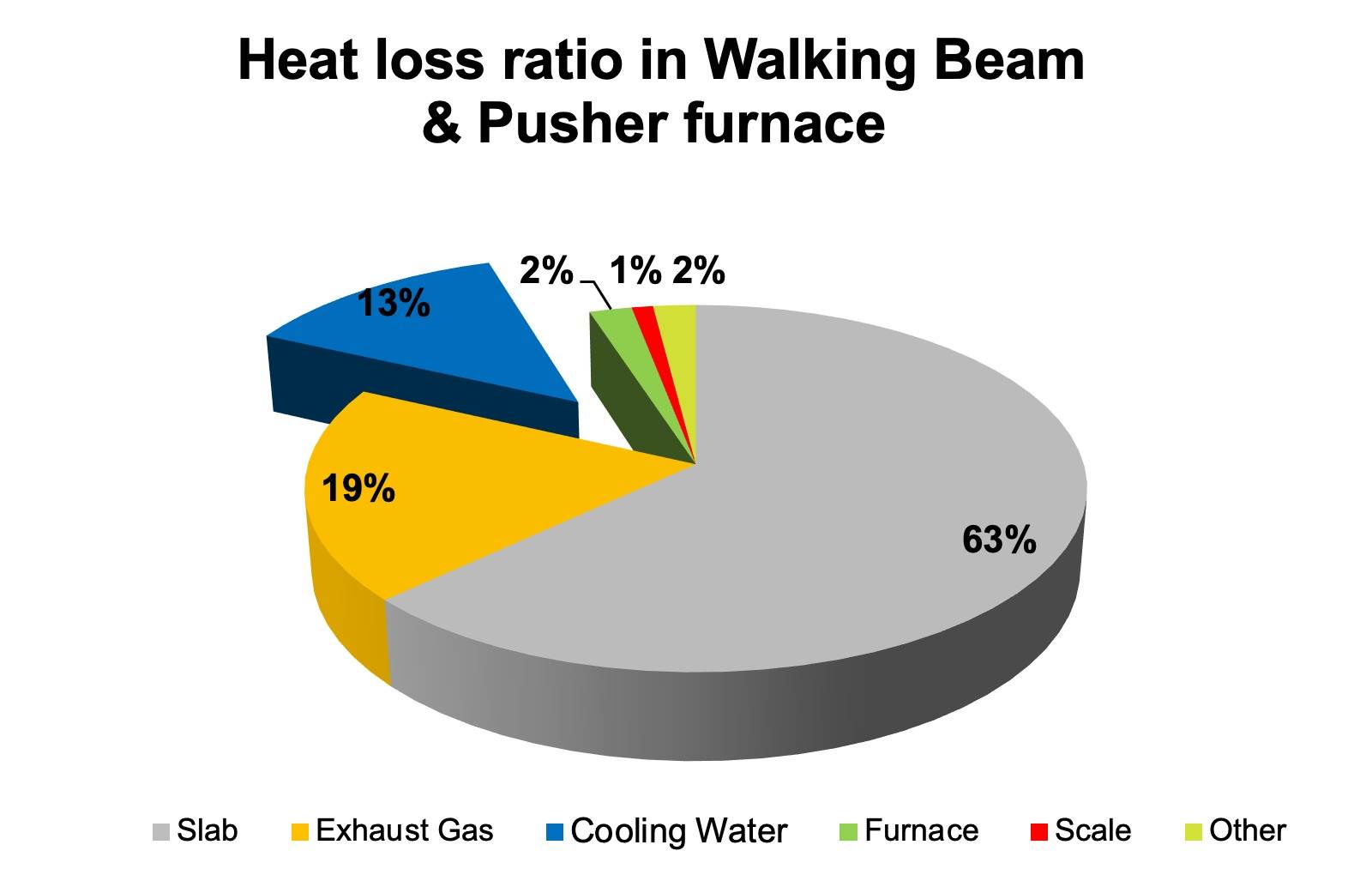

Save Energy & Reduce Downtime in Walking Beam Furnaces

- Insulate Skids & Posts with ULTC Pads, Saving Cooling Water Energy up to 15%

- Protects Metals from Thermal Degradation

- Can be Used under Refractory Castables or Precast Shapes

- Easy Installation, Wrap on Metal before Refractory Lining

- Reduce Water Leakages & Immediate Fuel Savings Proven

Reduce Heat losses & Increase Volume in Ladles & Tundish with Microporous

- Up to 40% More Insulating Than Ceramic Fibre

- Reduces Heat Losses in Ladles (LRF, Tundish, Torpedo) up to 25%

- Increases Volume by Reducing Insulating Layer Thickness

-

Water Repellent Grades Available for Direct Refractory Casting

Lanexis is Trusted By