OUR SOLUTIONS

Transforming Efficiency and Performance with Innovative Cement Industry Solutions from Lanexis

Request a free sample

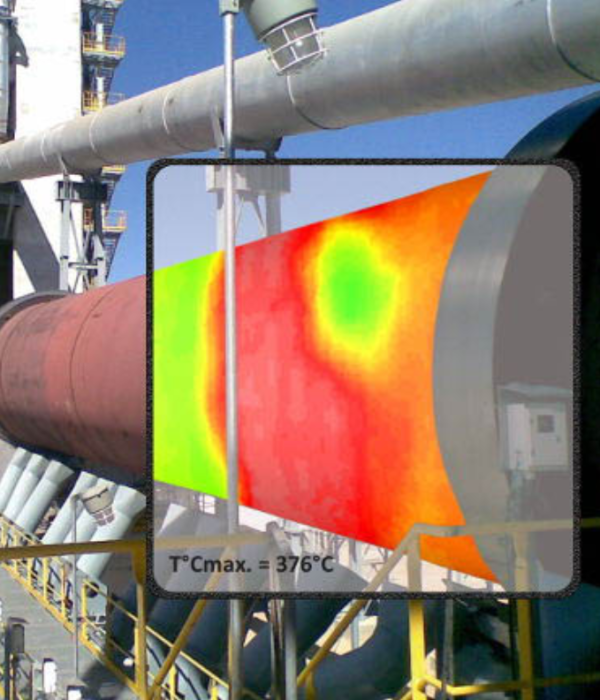

Save Energy in Rotary Kiln & Coolers

- Achieve up to 10% Fuel Reduction

- Reduced NOx air emissions by more than 5%

- Reduced CO2 air emissions by 7%

- Through Reduction of lost heat

Ultra Low Thermal Conductivity Insulation for TAD

- Greatly Reduce Heat Losses upto 25%

- High Thermal Stability Upto 1100*C

- Replacement of Calcium Silicate- insulation properties do not reduce over time

- No Change in current lining process

- Get extra Gas Temperatures upto 40*C

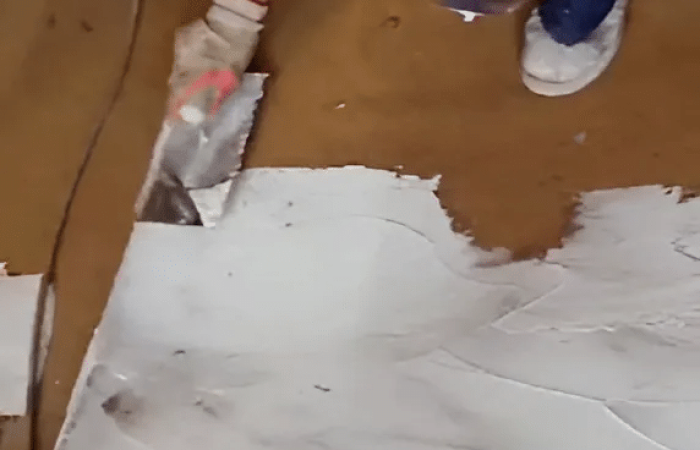

Reduce Rotary Kiln Heat Losses with High Strength Liquid Insulation

- It reduces heat losses upto 15% with 2-3mm thickness.

- The ONLY workable solution in Rotary Kilns

- Withstands continuous operating temperatures upto 600*c.

- Our Liquid Insulation is applied inside the Rotary Kiln Steel shell before refractory lining

Reduce Corrosion of Rotary Kiln Shell with High-Temperature Acid/Alkali Resistant Coatings

- Excellent Protection From Corrosion caused by use of Alternate Fuels

- Our Coating does not Crack With High Temperatures

- Enhance and Extend the life of the shell

-

It can be troweled or sprayed,

Brick lining can start immediately after coating

Lanexis is Trusted By