Request a free sample

Key Features

Resists a wide range of chemicals/acids including oxidizing & concentrated acids (except hydrofluoric)

Excellent flexural & compressive strength suitable for high stresses even in immersed conditions

Resistant to temperatures up to 700°c

Designed for extended service life in harsh chemical environments, reducing the need for frequent replacements

Our Range

Durabrick® AR HTA

Durabrick® AR HTB

Durabrick® AR Class I

Acid/Alkali Resistant Bricks Range

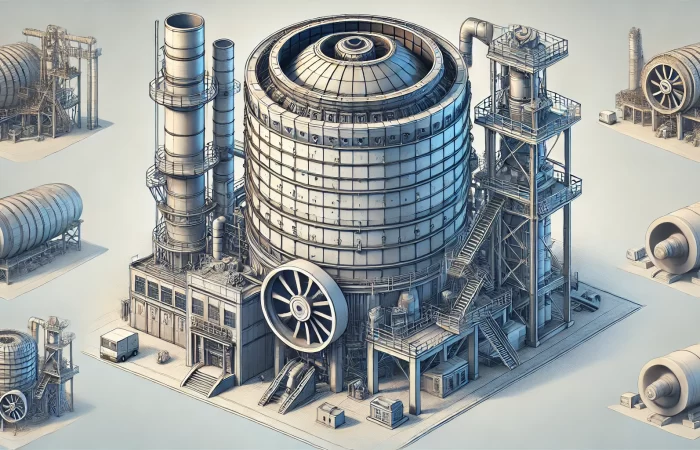

DURABRICK® acid resistant silica bricks are high-performance acid and chemical-resistant silica bricks, crafted from premium silica and select raw materials through advanced extrusion and dry pressing techniques.

Available in thicknesses ranging from 25mm to 400mm, these bricks are designed to withstand harsh chemical environments and high temperatures, making them ideal for use in acid storage tanks, towers, quenchers & secondary containment. They exceed ASTM C 279-17 standards ensuring their superior quality and reliability.

Technical Specifications

| Property | Specification |

|---|---|

| Modulus of Rupture (Flexural Strength) | Minimum 10.3 MPa (1500 psi) |

| H₂SO₄ Solubility (Acid Solubility) | Maximum 2% weight loss, exceeding ASTM C-279 requirements |

| Low Water Absorption | Maximum 1.5% |

| Bulk Density | 140-145 lbs./cu. ft. |

| Compressive Strength | Up to 100 MPa |

| Temperature Resistance | Up to 700°C (1292°F) |

Sustainable, & reliable energy systems, Find Your Solution Now!

Features

Know More About

The Product

Highly chemical resistant:

Excellent resistance from a wide range of chemicals/acids including oxidizing & concentrated acids (except hydrofluoric)

High Strength:

Excellent flexural & compressive strength suitable for high stresses even in immersed conditions

High temperature resistance:

Resistant to temperatures up to 700°c

Increased Longevity:

Designed for extended service life in harsh chemical environments, reducing the need for frequent replacements.

Applications

Pioneering Solutions for Tomorrow's Challenges

Chemical Reactors

Acid Storage Tanks & Tank Farms

Battery Breaking Units

Priiling Tower Lining

Pickling Lines

Secondary Containment

0

+

Years of Experience

0

+

Numbers of Customers Worldwide

0

+

Number of Projects Covered

0

Metric Tons of Carbon Emissions Reduction

Why Buy This Over Competition

Lanexis is an internationally trusted engineering company, offering comprehensive refractory, acidlining, and insulation solutions. Our technical team collaborates closely with customers to customize products for improved efficiency and cost-effectiveness. With professionally managed operations and swift response times, we provide seamless support from offers to after-sales service.

Active Customers

0

+

Technical Support?

Lanexis also provides design, engineering, and installation support worldwide.

Lanexis is Trusted By

Innovation and Excellence

Advantages at Lanexis

Comprehensive Protection:

Our Anti-Acid linings & corrosion resistant solutions are effective against a broad spectrum of acids and alkalis for reliable long-term performance. Our linings have been proven in various industries and used for decades under extreme conditions.

Customization:

If you have any specific requirements or duty conditions which need a customized lining for any demanding environments. We have solutions for corrosion protection under high temperature environments. We can customize linings to meet specific customer needs.

Technical Support:

We provide design, engineering, failure analysis- rectifications and corrosion audits. Whether you require inspection, supervision services for new linings or revamps, updated lining drawings- we provide complete technical support.

Contact Lanexis today for tailored Acid/Alkali Resistant Bricks solutions!

Reach out to Lanexis today for customized solutions designed to meet your unique requirements with top-notch quality and performance!

For further inquiries

Have Questions? We’re Here to Help! If you have any questions or need further information, Our team is ready to assist you with any inquiries you may have.