Request a free sample

Key Features

-

Low Creep

-

Exceptional hot load strength

-

Excellent Thermal Shock Resistance

-

High Chemical Resistance

-

High Fired

Our Range

-

Durabrick® 90HF

-

Durabrick® 99HF

Corundum Refractories Range

Durabrick® 90HF & 99HF

These bricks exhibit outstanding characteristics such as low creep, exceptional hot strength, high thermal stability & chemical resistance. They are designed to withstand corrosion in both oxidizing and highly reducing atmospheres, as well as high-temperature hydrogen attacks.

Available in standard brick sizes (straight, arches, and wedges) and custom plates and shapes, Lanexis Corundum Bricks are extensively used in industries such as fertilizer production, petrochemical SRU’s, Carbon Black, and alloy steel.

Technical Specifications

-

Al2O3 purity up-to 99.5%

-

Service Temperatures upto 1850c (3362F)

-

100% ultra-high temperature sintered

-

Apparent Porosity: ≤ 17%

-

Fe2O3 Content: ≤ 0.2%

-

Excellent Cold Crush Strength: >145MPa (21000psi)

Sustainable, & reliable energy systems, Find Your Solution Now!

Features

Know More About

The Product

High Thermal Stability:

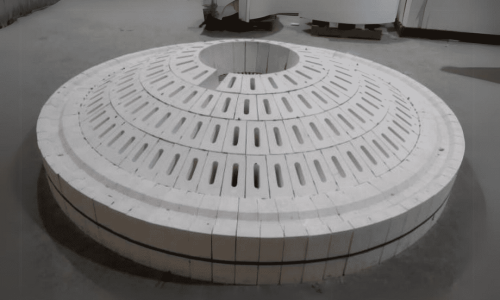

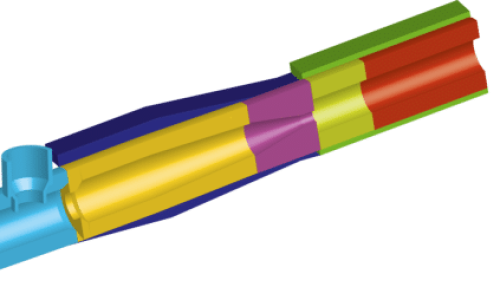

Made from high-purity tabular alumina and fused alumina, corundum bricks offer exceptional thermal stability, high purity and high density, resulting in superior mechanical strength and stability under extreme conditions.

Ultra Low Creep:

Low creep is an important feature of Durabrick 90HF & 99HF. They exhibit minimal deformation over time at high temperatures which enhances their longevity, improves thermal stability & increases slag resistance.

Excellent Thermal Shock Resistance:

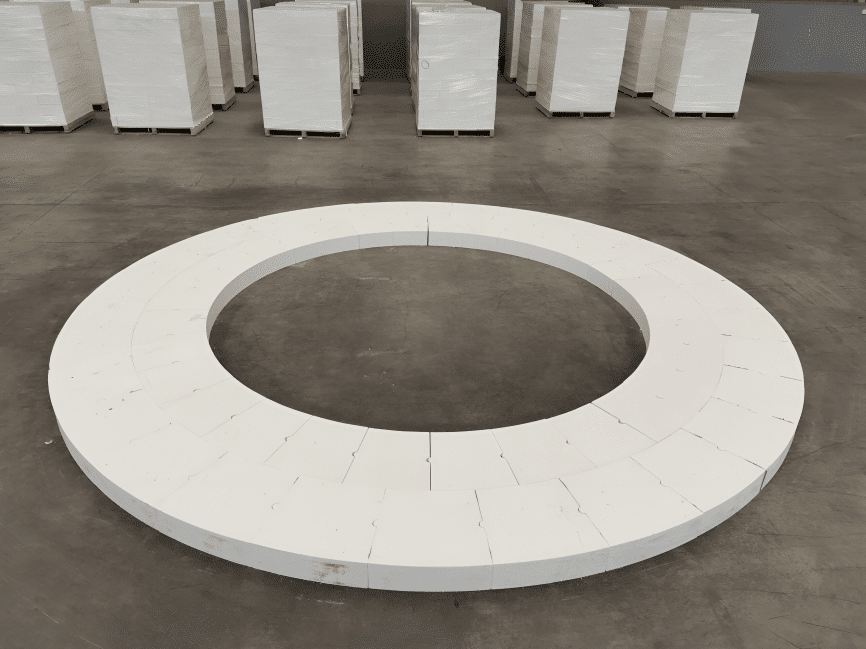

Designed to withstand rapid temperature changes, corundum bricks offer outstanding thermal shock resistance, making them ideal for environments where temperature fluctuations are common.

Chemical Resistance:

Lanexis Corundum bricks are highly resistant to corrosive environments, including oxidizing and highly reducing atmospheres, as well as high-temperature hydrogen attack. This makes them suitable for a wide range of chemical processes.

Applications

Pioneering Solutions for Tomorrow's Challenges

Sulphur Recovery Units

Carbon Black Reactor

Secondary reformers Domes & Linings

0

+

Years of Experience

0

+

Numbers of Customers Worldwide

0

+

Number of Projects Covered

0

Metric Tons of Carbon Emissions Reduction

What are Durabricks®?

Durabricks ® are premium refractory bricks offered by Lanexis, designed for superior performance and

extended service life. These high-quality bricks are engineered for a range of applications providing exceptional

durability and high thermal stability. The Durabrick® range includes mullite, andalusite, corundum, insulation &

alumina-chrome grades

Active Customers

0

+

Technical Support?

Lanexis also provides design, engineering, and installation support worldwide.

Lanexis is Trusted By

Innovation and Excellence

Advantages at Lanexis

Energy Saving Refractories:

We can reduce energy consumption upto 20%. Lanexis is a leader in reducing fuel consumption of your furnaces through innovative lining matrix, advanced products like High Emissivity coatings & Microporous Insulation.

Customization:

Need specific shapes, sizes, grades or change in refractory properties? Our in-house R&D team allows Lanexis to continuously innovate and customize refractories to meet specific customer needs.

Technical Support:

We provide design, engineering, failure analysis- rectifications and thermal audits for furnaces. Whether you require updated refractory drawings or thermal calculations for a higher energy efficient refractory lining design- we provide complete technical support.

Contact Lanexis today for tailored Corundum Refractories solutions!

Reach out to Lanexis today for customized solutions designed to meet your unique requirements with top-notch quality and performance!

For further inquiries

Have Questions? We’re Here to Help! If you have any questions or need further information, Our team is ready to assist you with any inquiries you may have.