Request a free sample

Products Range

High Alumina Refractories

Manufactured with high purity sintered bauxite and select clays. These are versatile bricks for temperatures ranging upto 1500c (2732F).

Lanexis also offers dense grades with low porosity, high strength and hot load strength. These bricks also comprise of Medium -High- Superduty Bricks.

Our Range:

-

Durabrick 50

-

Durabrick 50S

-

Durabrick 50Dz

The 60% alumina range is wide and produced from calcined bauxitic kaolin and high purity clays with low impurities. These brick are used in the steel industry, as well as rotary kilns. As a result of firing to high temperature, these bricks have low porosity, excellent strength and creep resistance, and good thermal stability at high temperatures. Phos bonded grades are available.

Our Range:

Durabrick® 60

Durabrick®62D

Durabrick® 60P

Durabrick® 65

Durabrick® 65S

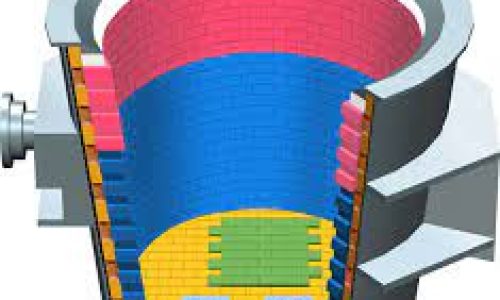

70% Alumina bricks are the most widely used refractory brick because of its excellent performance in multiple environments. These bricks have superior high- temperature strength and refractoriness and controlled porosity.

70% RKB’s offer high expansion which is beneficial for a tight fit in Rotary Kilns.

Applications include the steel-industry and various rotary kilns. The Phosphate bonded grades offer higher strength and plasticity.

Our Range:

Durabrick® 70

Durabrick® 70Li

Durabrick® 70P

Durabrick® 75

Durabrick® 70D

Durabrick® 70S

Lanexis 80% alumina bricks are manufactured with high quality calcined bauxite from South America. We also add various amounts of other fine aluminas and clays for superior performance.

Our 80% bricks offer excellent strength and thermal shock resistance. They are resistant to most slag conditions present in steel ladles.

The mullite bonded phosphate grade offers higher thermal shock resistance and excellent alkali rating at high temperatures.

Our Range:

Durabrick® 80

Durabrick® 80LF

Durbrick 80P

Durabrick® 85

Durabrick® 85P

90-99% Corundum & Mullite based bricks are extremely high performance, high-quality bricks. They exhibit very low creep, very good thermal shock resistance and excellent hot load strength For high temperatures up to 1850 °C (3362F).

Capable of handling very difficult applications- These are used in Petrochemical, Slphur Recovery Units (SRU), Carbon Black Reactors, Secondary Reformer Domes & slagging rotary kilns, where it resists corrosion and penetration by slag.

Our Range:

Durabrick® 90

Durabrick® 90HF

Durabrick® 90P

Durabrick® 99HF

Durabrick® 99D

“Latest Innovation in the World of Refractories”

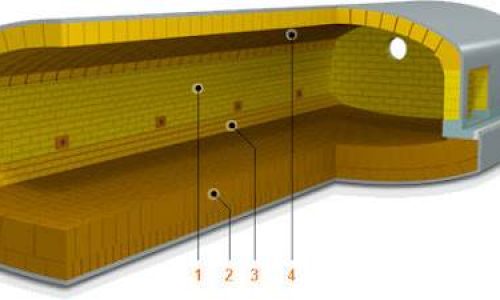

Lanexis innovative Silica Mullite Bricks offer high strength with inbuilt insulation, thermal shock resistance & low thermal conductivity.

The innovation is the development & blending of high strength insulating backup material with a density of 1.8g/cm3 & still highly insulating.

Our Hybrid range of refractories can save up to 25% of heat losses in rotary kilns, ladles & static furnaces providing unmatched thermal performance and quick ROI.

Contact us today to take up trials in your furnaces.

Sustainable, & reliable energy systems, Find Your Solution Now!

Features

Know More About

The Product

Very high refractoriness, slag and metal corrosion resistance

High Fired 90% & 99% Bricks provide excellent creep resistance

Very high abrasion resistance, chemical & thermal stability

Excellent Thermal shock resistance

Applications

Pioneering Solutions for Tomorrow's Challenges

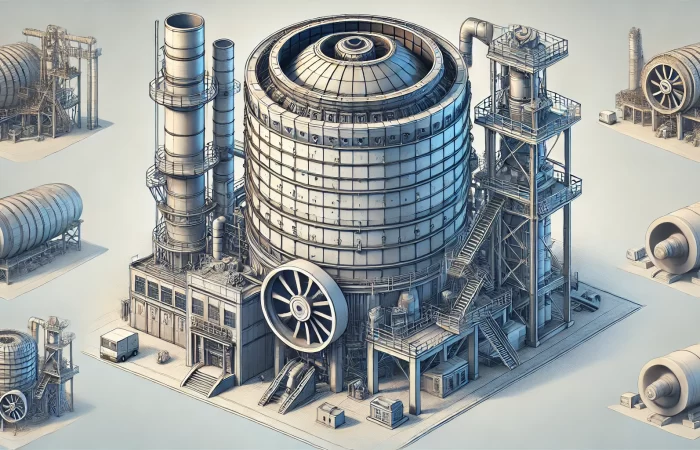

Reheat Furnaces

Steel Ladles

High Temperature Furnaces

Lining for rotary kilns

Boilers

Melting furnaces

0

+

Years of Experience

0

+

Numbers of Customers Worldwide

0

+

Number of Projects Covered

0

Metric Tons of Carbon Emissions Reduction

What are Durabricks®?

Durabricks ® are premium refractory bricks offered by Lanexis, designed for superior performance and

extended service life. These high-quality bricks are engineered for a range of applications providing exceptional

durability and high thermal stability. The Durabrick® range includes mullite, andalusite, corundum, insulation &

alumina-chrome grades

Active Customers

0

+

Technical Support?

Lanexis also provides design, engineering, and installation support worldwide.

Lanexis is Trusted By

Innovation and Excellence

Advantages at Lanexis

Energy Saving Refractories:

We can reduce energy consumption upto 20%. Lanexis is a leader in reducing fuel consumption of your furnaces through innovative lining matrix, advanced products like High Emissivity coatings & Microporous Insulation.

Customization:

Need specific shapes, sizes, grades or change in refractory properties? Our in-house R&D team allows Lanexis to continuously innovate and customize refractories to meet specific customer needs.

Technical Support:

We provide design, engineering, failure analysis- rectifications and thermal audits for furnaces. Whether you require updated refractory drawings or thermal calculations for a higher energy efficient refractory lining design- we provide complete technical support.

Contact Lanexis today for tailored High Alumina Refractories solutions!

Reach out to Lanexis today for customized solutions designed to meet your unique requirements with top-notch quality and performance!

For further inquiries

Have Questions? We’re Here to Help! If you have any questions or need further information, Our team is ready to assist you with any inquiries you may have.