Request a free sample

Products Range

Insulating Fire Bricks

Durabrick® IFB 2300-3200 series offer an Ultra-low thermal conductivity due to their uniform micro-nano-sized pore structure. Our Insulating firebricks are fabricated into different grades with ability to operate in environments from 1260C (2300 F) to (1760C) 3200 F.

Features:

No burnout material- Hot Face Insulation

More light & More energy efficient

Low reheating linear change

High strength

High Dimensional Accuracy

Our Range:

Durabrick® IFB 23, 26, 28, 30, 32

Durabrick® IFB 23ES & 26ES are our latest low density, low thermal conductivity ‘Energy Saving’ range of IFB’s manufactured from the foaming process.

“Upto 30% lower density”

“Ultra Low thermal conductivity”

Our energy saving bricks serve for applications in industries such as Petrochemicals, Metals, Ceramics, and Glass, where it is essential to reduce heat losses and lower refractory heat storage.

Our Range:

Durabrick® IFB 23ES,

Durabrick® IFB 26ES

Durabrick® BA 90 & 99 are bubble alumina insulation bricks which can operate up to 1,850°C (3,362°F) These bricks exhibit exceptional hot strength and low thermal conductivity making them ideal high-temperature ceramic kilns, lab furnaces and insulators for applications up to 1850°C.

Specifications:

Material Composition: High purity bubble alumina

Additives: High property micro powder

Shaping Method: Vibration press

Sintering Temperature: Over 1700°C

Classification Standard: ASTM C155

Our Range:

Durabrick® BA 90

Durabrick® BA 99

Hot Face Kyanite (HFK) insulation bricks are widely used, cost effective bricks which are primarily used as the working face in furnaces, kilns, and other high-temperature processing equipment.

Features:

High Temperature Resistance:

Withstand temperatures up to 1,260°C (2,300°F)

Low Thermal Conductivity: Improving energy efficiency in high-temperature applications.

Kyanite provides High Strength and Durability

HFK bricks are resistant to thermal shock, mechanical wear, and chemical attack.

Lightweight Despite their strength

Our Range:

HFK 140

HFK 150

We also offer high performance diatomite & molar insulation bricks on request. These bricks are used for specialized applications with high strength and low density.

• High strength,

• Low heat capacity

• Low thermal expansion

Their thermal shock resistance is high due to low thermal expansion and contraction factors. They have low permeability against gases and resistance to weak acids. These insulation bricks are used as back-up insulation in the industrial furnaces.

Sustainable, & reliable energy systems, Find Your Solution Now!

Features

Know More About

The Product

Low Reheat Change:

Low PLC results assured safety in application and long life span.

Low Thermal Conductivity:

Good thermal insulation makes thinner furnace walls possible, improving efficiency & lower operation cost, making a contribution to environmental protection.

Low Density & Low Heat Storage:

Due to lightweight and low thermal conductivity, bricks absorb less heat inward, which means reduced fuel cost and fast heating up in cyclical operation heating equipment.

High Purity:

Low in impurity like Iron & alkali flux content to realize refractory performance in specified atmosphere.

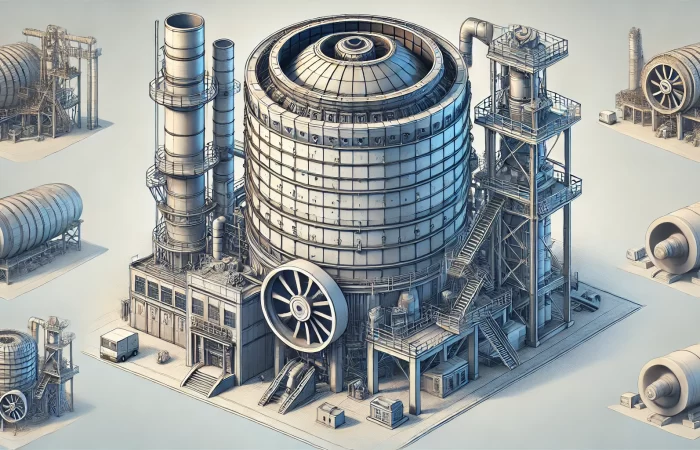

Applications

Pioneering Solutions for Tomorrow's Challenges

Petrochemical industry kilns

Iron & steel industry coke ovens

Reheating Furnace Backup

High Temperature Shuttle Kilns

Aluminum industry anode baking furnace

High Temperature Laboratory Furnaces

0

+

Years of Experience

0

+

Numbers of Customers Worldwide

0

+

Number of Projects Covered

0

Metric Tons of Carbon Emissions Reduction

What are Durabricks®?

Durabricks ® are premium refractory bricks offered by Lanexis, designed for superior performance and

extended service life. These high-quality bricks are engineered for a range of applications providing exceptional

durability and high thermal stability. The Durabrick® range includes mullite, andalusite, corundum, insulation &

alumina-chrome grades

Active Customers

0

+

Technical Support?

Lanexis also provides design, engineering, and installation support worldwide.

Lanexis is Trusted By

Innovation and Excellence

Advantages at Lanexis

Energy Saving Refractories:

We can reduce energy consumption upto 20%. Lanexis is a leader in reducing fuel consumption of your furnaces through innovative lining matrix, advanced products like High Emissivity coatings & Microporous Insulation.

Customization:

Need specific shapes, sizes, grades or change in refractory properties? Our in-house R&D team allows Lanexis to continuously innovate and customize refractories to meet specific customer needs.

Technical Support:

We provide design, engineering, failure analysis- rectifications and thermal audits for furnaces. Whether you require updated refractory drawings or thermal calculations for a higher energy efficient refractory lining design- we provide complete technical support.

Contact Lanexis today for tailored Insulating Fire Bricks solutions!

Reach out to Lanexis today for customized solutions designed to meet your unique requirements with top-notch quality and performance!

For further inquiries

Have Questions? We’re Here to Help! If you have any questions or need further information, Our team is ready to assist you with any inquiries you may have.