Request a free sample

Key Features

-

Energy Saving- Reduces heat losses upto 20%

-

Space Saving, thickness of only 80-120 Mils (2-3 mm)

-

Acid Resistant: Protects the Steel Shells from detrimental corrosion attack.

-

Temperature Resistance upto 1100°F (600°C)

-

Reduces the hot spots & skin temperature of equipments

-

Easy to Install- Trowel Application

Our Range

-

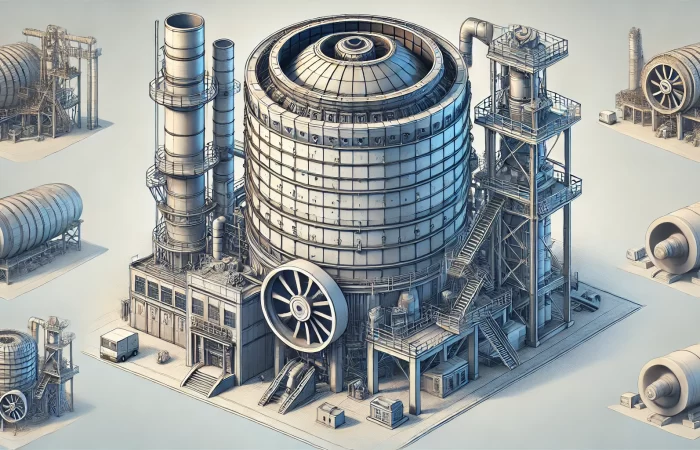

Rotary Kilns for Mineral Calcination, Cement, DRI, Pulp & Paper

-

High Temperature Furnaces & Kilns

-

Reheating & Forging Furnaces

-

Ladle Backup- LRF, Torpedo & Transfer Ladles

-

Hot Air Ducts, Recuperators & Steam Pipelines

-

Waste Heat Transfer Ducts

Liquid Insulation Li1100 Range

INSULAIRR® Li 1100 is a two component coating which is pre mixed and applied directly to the steel shell from inside before the refractory lining as backup. This blocks heat losses which improves thermal efficiencies in Furnaces, Rotary Kilns, Ladles, Tundishes, hot air & gas ducting systems by arresting the heat within the equipment.

Its anti-corrosion properties resists acid attack on the steel shell. When installed there remains no air gap between the coating & shell.

Technical Specifications

Density after Drying: 37 lb/ft³ (0.59 g/cm³)

Recommended Coating Thickness: 2-3 mm (80-120 mils)

Continuous Use Temperature: 500°C (932°F)

Thermal Conductivity (Hot Face Temperature):

-

@ 400°F: 0.55 Btu-in/ft²·hr·°F

-

@ 750°F: 0.70 Btu-in/ft²·hr·°F

Hardness (After Drying): Mohs 6H

Sustainable, & reliable energy systems, Find Your Solution Now!

Features

Know More About

The Product

Energy Efficient

Reduces heat losses by up to 20%, enhancing overall energy savings and operational efficiency.

Space Efficient

Provides high insulation performance with a minimal thickness of just 80-120 mils (2-3 mm), optimizing space utilization.

High Temperature Resistance

Withstands temperatures up to 1100°F (600°C), making it suitable for demanding high-temperature applications.

Corrosion and Thermal Degradation Protection

Shields steel substrates from thermal degradation and acid corrosion, extending equipment lifespan and reducing maintenance needs.

Applications

Pioneering Solutions for Tomorrow's Challenges

Rotary Kilns for Mineral Calcination, Cement, DRI, Pulp & Paper

High Temperature Furnaces & Kilns

Reheating & Forging Furnaces

Ladle Backup- LRF, Torpedo & Transfer Ladles

Hot Air Ducts, Recuperators & Steam Pipelines

Waste Heat Transfer Ducts

0

+

Years of Experience

0

+

Numbers of Customers Worldwide

0

+

Number of Projects Covered

0

Metric Tons of Carbon Emissions Reduction

Why Buy This Over Competition

Lanexis is an internationally trusted engineering company, offering comprehensive refractory, acidlining, and insulation solutions. Our technical team collaborates closely with customers to customize products for improved efficiency and cost-effectiveness. With professionally managed operations and swift response times, we provide seamless support from offers to after-sales service.

Active Customers

0

+

Technical Support?

Lanexis also provides design, engineering, and installation support worldwide.

Lanexis is Trusted By

Innovation and Excellence

Advantages at Lanexis

Customized Solutions

Lanexis offers customized calcium silicate insulation solutions tailored to your specific requirements, ensuring optimal performance and cost-effectiveness across various industries and applications.

Quality Assurance

We prioritize quality in our products and services, ensuring that our calcium silicate insulation meets the highest standards of performance, reliability, and durability, providing you with confidence and peace of mind in your investment.

Responsive Support

With Lanexis, you can expect responsive and dedicated customer support throughout the entire process, from consultation to installation and beyond. Our team is committed to providing prompt assistance, timely updates, and proactive problem solving to meet your unique needs and challenges.

Contact Lanexis today for tailored Liquid Insulation Li1100 solutions!

Reach out to Lanexis today for customized solutions designed to meet your unique requirements with top-notch quality and performance!

For further inquiries

Have Questions? We’re Here to Help! If you have any questions or need further information, Our team is ready to assist you with any inquiries you may have.