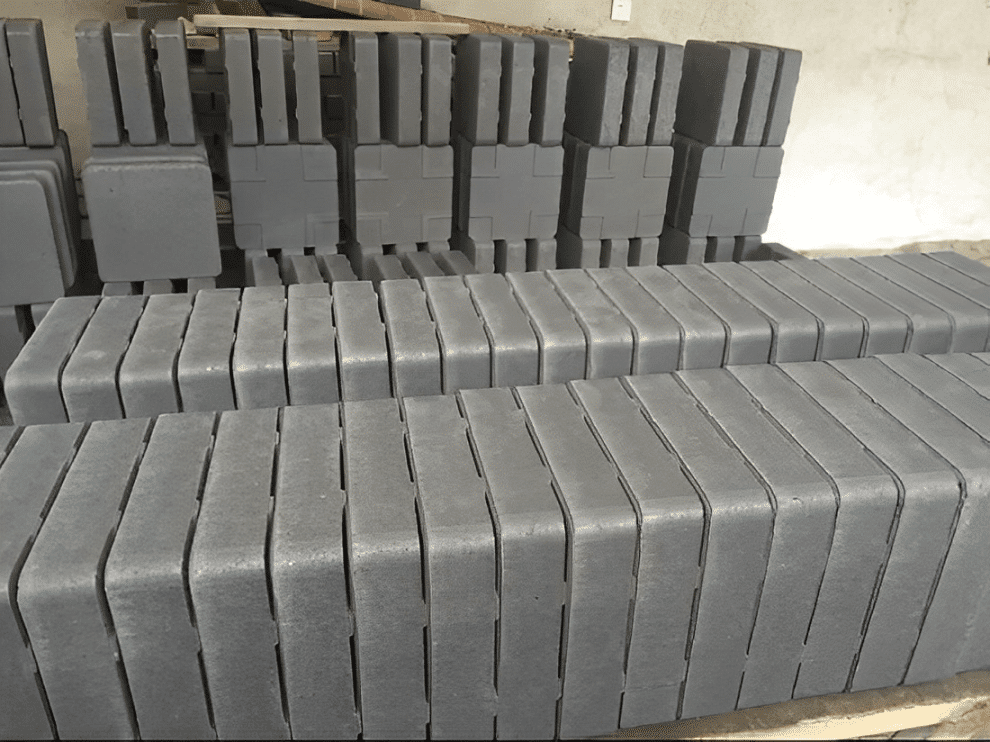

Andalusite Bricks

Andalusite bricks are refractory bricks made from andalusite, a raw material, and other powders. They are used in various industries, including steelmaking, glass melting, and hazardous waste incineration. They are used in applications requiring low creep, high thermal stability, high thermal shock & spall resistance and corrosion resistance.