OUR SOLUTIONS

Elevating Sulphuric Acid Production Efficiency with Lanexis

Request a free sample

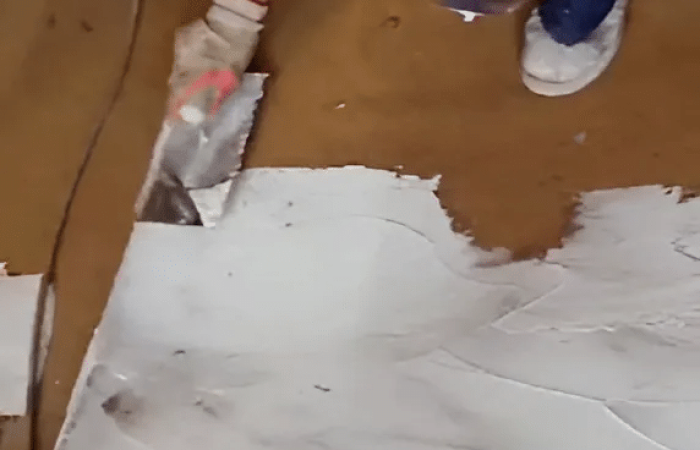

Complete SAP Tower & Tank Linings

- Acid Resistant Lining for Sulphuric Acid Towers: (IAT, DT, FAT & Tanks)

- Customized designs for self-supporting Domes, match marked for fast installation

- High Strength, High Alumina Grid Bars & Grid Blocks for Tower durability

- Specialized Corrosion Resistant Membranes for Tower Backup

Reduce Corrosion Related Downtime

- Acid Resistant Brick Lining for Storage Tanks, Reactors & Secondary Containment Areas

- Range of High-Performance Mortars including Furane, Potassium Silicate, Novoalc

- Acid Resistant Rubber Lining Solutions for Equipment Protection

- Customized Shapes, Sizes & Thickness Available with Low Lead Time

Optimized Tower Maintenance Services

- Regular Inspection and Maintenance Services for Sulphuric Acid Towers

- Predictive Maintenance Strategies to Identify Potential Issues Before They Occur

- Rapid Response Teams for Emergency Repairs and Maintenance

- Proactive Maintenance Planning to Minimize Downtime and Production Losses

Tower Packing Solutions

- Advanced Tower Packing Systems for Sulphuric Acid Towers

- Enhanced flow to Improve Tower Efficiency

- Utilization of High-Efficiency Random & Structured packing solutions

- Customized Packing Solutions Tailored to Specific Tower Designs and Operating Conditions

Corrosion Monitoring and Control Systems

- Integrated Corrosion Monitoring Systems for Sulphuric Acid Towers

- Real-Time Monitoring of Corrosion Rates and Environmental Conditions

- Automated Alerts and Notifications for Early Detection of Corrosion Issues

- Implementation of Corrosion Control Measures to Extend Tower Lifespan and Ensure Operational Integrity

Lanexis is Trusted By